There are many well-known tanks across the world, but few can match the legendary T-72. Produced in several countries in large numbers, this ubiquitous workhorse of the former Warsaw Pact saw service in countless conflicts and proved itself to be one of the most popular military export vehicles of the Cold War era. In this article, we will be focusing on the T-72B model.

T-72B Model 1985

Development of the T-72B was based on a Soviet government decision from July 5 1981. The development process itself took place in Uralvagonzavod and was part of a broader T-72A Improvement program, which included a large number of different prototype upgrades to the T-72A Main Battle Tank.

One of the projects in this program was given the designation Object 184. Six different turret designs were developed as part of the project, each with different armor layouts, armaments and fire control systems. Several prototypes were built and tested thoroughly between 1981 and 1984. The winner was officially accepted into Soviet army service under the T-72B designation on October 27 1984. This decision was confirmed in a Ministry of Defense directive from January 23 1985, which is likely why various sources cite 1984 or 1985 as the year of the T-72B's introduction.

Compared to the earlier T-72A design, there were two major upgrade areas:

- Protection

- Firepower

Armor protection was enhanced with the introduction of the Kontakt Explosive Reactive Armor kit, which was cutting-edge at the time. It consisted of 227 separate containers, located on the frontal half of the hull and turret front and sides, protecting the vehicle against first generation guided missiles. It's worth noting that the T-72B ERA layout was changed (improved) compared to the T-72AV (a T-72A variant, equipped with the same ERA kit). The first generation Kontakt ERA was capable of defeating warheads with approximately 700mm of penetration. A more powerful missile (or a tandem warhead) was required to penetrate this set.

T-72B in Georgia

The frontal turret armor was also improved with the turret shape changed somewhat. The noticeable frontal turret armor extensions (cheeks) were made, due to the different composite armor layout, even more prominent. The Americans nicknamed this turret variant Super Dolly Parton.

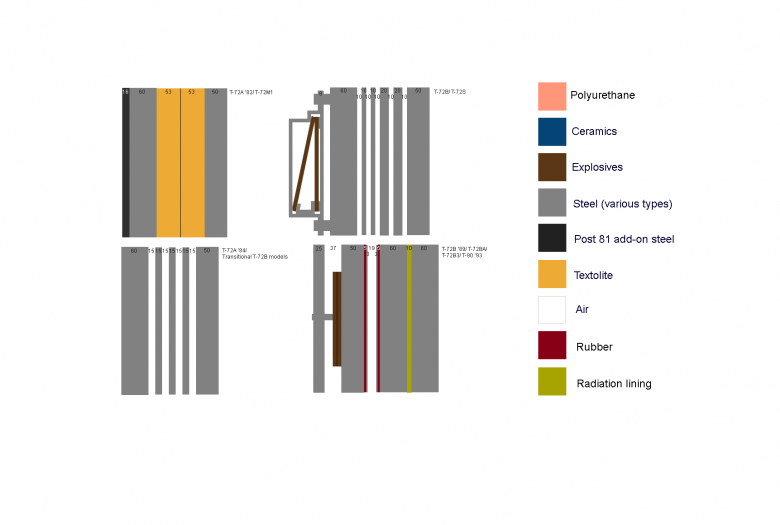

The hull armor composition was also changed. The original T-72A upper frontal plate consisted of the following layers (from the outside to the inside):

- 60mm steel plate

- 53mm textolite layer

- 53mm textolite layer

- 50mm steel plate

An additional 16mm steel plate was added to the T-72A model 1982 (and to the derived T-72M1). The textolite layers were removed in late models of the T-72A and the early models of the T-72B.

T-72B upper frontal plate schematics by Artem Gavrilov

They were replaced with layers of plates with gaps in between, so there was:

- 60mm steel plate

- Three 15mm steel plates with 15mm gaps between them

- 50mm steel plate

This structure was changed in later T-72B models, as follows:

- 60mm steel plate

- Two 10mm steel plates with 10mm gaps between them

- Two 20mm steel plates with 10mm gaps between them

- 50mm steel plate

This complex layout was equal to approximately 460mm to 480mm of RHA versus kinetic rounds and made the upper frontal plate immune to the destructive effect of HESH shells. It's worth noting that the T-72S (the export variant of the T-72B) uses the same frontal plate layout.

Additional protection measures for the T-72B also included:

- Improved protection from radiation, both for the entire vehicle (lining) and for individual crew members

- 902B Tucha smoke grenade launchers

- Soda anti-napalm system

- Rapid deployment 3 EC 13 Iney fire suppression system

Firepower was also significantly increased with the introduction of the new, modernized 125mm 2A46M gun with the 9K120 Svir guided missile launching system, allowing the tank to fire 9M119 guided missiles from its gun. The Svir missile is a laser beam rider, capable of hitting enemy tanks at 4000 meters with 80 percent accuracy and penetrating between 600mm and 650mm of RHAe.

The vehicle was also equipped with the new 1A40-1 fire control system and TPD-K1 optics with laser rangefinder and automatic compensator, allowing aim to be adjusted for temperature, atmospheric conditions, target speed and several other factors and significantly increasing the chance of hitting with the first shot.

T-72B

The gun also received a new stabilizer (designation 2E42-2). Facing forward with the stabilizer disabled, the gun could elevate to +13 degrees and depress to -6 degrees. The rate of fire was 8 rounds per minute. The vehicle carried 45 rounds (22 directly in the autoloader).

And last but not least, the vehicle also received a new communications set (designation Abzac), consisting of a R-173 UHF radio, R-713P receiver and accessories. The set had a range of approximately 20km.

As a result, the weight of the vehicle increased from 41 tons to 44.5 tons. In order for the vehicle to keep its mobility, the 780hp V-46-6 diesel engine of the T-72A was replaced with an 840hp V-84-1 (some sources use the V-84M designation) multi-fuel four stroke 12-cylinder diesel.

The T-72B was produced between 1985 and 1992, gradually replacing the T-72, and it remains one of the mainstays of Russian armored forces, along with the T-90.

There were multiple versions of the vehicle:

- T-72BK – commander variant with an R-130 radio set and TNA-4 navigation system

- T-72B-1 – a variant without the 9K120 Svir guided missile launching system

The biggest improvement during vehicle production was the T-72B model 1989 (sometimes incorrectly designated T-72BM) – a variant with improved protection, consisting of an enhanced Kontakt-5 ERA kit over the overhauled frontal armor. The layout of the upper front plate changed once again. This time, semi-reactive armor elements were included directly into the armor layout itself. The internal structure changed to:

- 25mm steel plate

- 37mm gap, partially filled with layers of explosives

- 50mm steel plate

- 5mm rubber layer, followed by 3mm steel plate

- 19mm gap

- 3mm steel plate, followed by 5mm rubber layer

- 60mm steel plate

- 10mm radiation lining

- 60mm steel plate

This complicated setup improved the protection against kinetic rounds to approximately 500mm-550mm of RHAe and to 600mm-900mm of RHAe versus HEAT rounds (numbers vary depending on sources). Please note that these numbers do not include the Kontakt-5 armor, which was mounted on top of the hull. This upper frontal plate layout was kept even in the latest T-72 variants and in the early T-90s.

T-72B (late model), destroyed in Ukraine

T-72Bs were only exported after the fall of the Soviet Union in the form of the 2001 upgraded variant T-72S. After production of the T-72B ended, a modernization process begun and it continues to this day. The T-72B3 is the latest mass-deployed variant of the T-72B, but these modernized variants will not be part of the Armored Warfare T-72B, which is based on the 1985 model. They will be covered in a future article.

Unlike its T-72A predecessor and the export T-72 variants, T-72B conflict participation was generally limited to the former Soviet republics. In Russian service, the T-72B participated in the failed assault on Grozny and, more recently, in the conflict in Ukraine.

Please note that the following information is classified as "in development" and may be subjected to change.

In Armored Warfare, the T-72B will replace the T-72A on Tier 6 in Marat Shishkin's T-series branch. The T-72A will (in historical configuration) appear on Tier 5 and the T-72 Ural will appear on Tier 4, alongside the Tier 4 T-64, which will be moved to a separate branch. The T-64 will then lead to a parallel T-80 branch.